I've done most of my reading with bell.

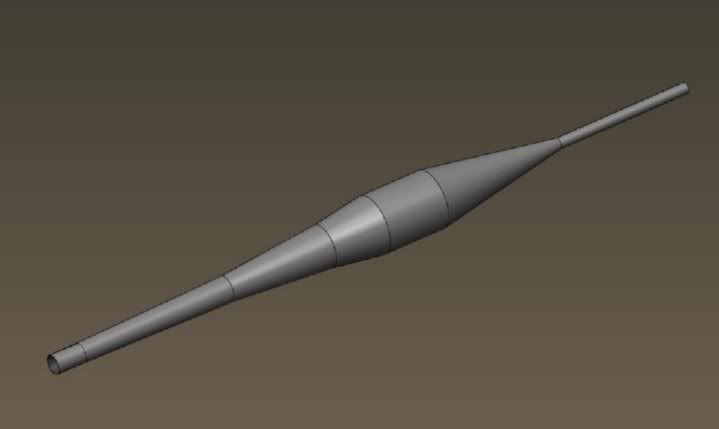

I did leave the transfers that low on purpose, didn't feel like messing with them. I did raise them on my other cylinder, just time consuming. I've gone through, some more thinking and I'm going to go for a 7500RPM peak. The manual for the YT175 shows 8200RPM when looking at ignition timing. The ports i set up pull very hard from the mid range up to the top with a stock pipe. I feel a pipe designed to take better advantage of that would be peaking around 7-8k. But I'd like my pipe to be inside the frame. Being it's in the frame, I have decided to go with a broad range of power with a skinnier pipe.

The temperatures is something that has got me on this program. It doesn't factor in compression at all, but it does suggest an exhaust wrap with these pipes. I'm going to have to go with the loosely extrapolated values based on fuel type. It gives 3 settings for fuel. Now being this engine is air cooled, I'm probably going to use a slightly larger stinger than the program suggest. Might hurt power some, but it'll keep the heat down. I've got a silencer off a blaster, so the stinger is going to fit that thing.

Now I have a few other programs to help with the pipe design, 1 gives what it calls "average gas temp" at 600*c. This give sound a speed of 592 m/s. This is with 8000RPM, same port timing/size, and power development at roughly 29hp.

For the most part, just about ANYTHING is better than stock lol

I just wanna go fast. If your not first, your last!!

Reproducing the Tecate CDI. Contact me if you need one. I'm most accessible on FaceBook. You can find me on the 1984-1987 Kawasaki Tecate KXT250 Group.

Reply With Quote

Reply With Quote [/IMG]

[/IMG]