Glad to see everyone is putting thinking caps on. How many of us have just bolted on a carb or pipe and rode around thinking we had the fastest ride around? (my hand is up).

I melted a hole through a piston on my RZ 500 exactly because of the scenario Billy brought up. I’d milled the heads down and did something really stupid (that’s another story) that really labored and heated the engine on an extended top end blast. During the rebuild I found what was causing the additional heat, so I just resolved the heating issue rather than solving the pinch point issue during the rebuild. A mechanic buddy called it when I showed him the melted slug, but because it had run fine for a few months prior I just put a new piston in and left it flawed which meant that my engine was not running properly. Such is life when you’re a punk kid and your daily driver is also your race bike! Not to mention it’s a little complicated to chuck a dual cylinder head.

Earlier on I posted something about flat top pistons in here. The reason it interests me is along the likes of what Billy said Yamahondaman did with the trick Honda head. KTM uses a flat top in their engines and their 250’s are making 50+ HP and pulling stumps to boot. I have a custom head on my 300 KTM made with high altitude in mind. It is awesome. Case in point buddy bought a 2012 300 KTM last week with an allegedly fresh engine. Factory specs say his is lighter, makes 20% more power and has a tighter gear ratio than mine, bla, bla, bla compared to my 10 year older hot rod it’s down on power in a pavement roll-on drag. That tells me that if I could copy the dome I have on my bike and fit a flat top into the Tri-Z I might have something. On top of that my bike runs very cool and has a ton of compression. I really need to measure it, but I’d be surprised if it was under 180psi and it runs on pump gas all day long. Regardless, 2 strokes have come a long way in 30 years, but not in any way we can’t duplicate or copy other than a power valve. If my bike can out run the same 10 year newer version with a few mods there is hope for the Tri-Z!

Yamahondaman’s dome shape is posted in the original Cool Head post which I see got locked over the past few days??Thought I’d re-post it here before it gets deleted forever. Would be nice to know if there were incorporated into the Cool Head dooms or not. A CNC programmer should be able to understand this.

“ this is what i use when i "re-do" the TRI-Z Head.. it kinda a copy of the "85" ATC and the "ATC 295's" i used to do ... they work pretty good ! show him this profile.”

:2708

N100G50G0G99G97

T0505M8

S800M3

X.44Z.05

G71U.04R.015

G71P101Q102U-.01W.001F.006

N101G0X2.75

G1Z0.0

X2.74Z-.005

Z-.01

X1.9Z-.165

G2X1.7Z-.245R.21

G3X.44Z-.585R.8

G1X.44

N102G0Z.05

S350

G70P101Q102F.0015

G0Z.2M9

X8.0Z8.0

T0500M5

M1

M30

%

Last edited by El Camexican; 01-29-2015 at 07:47 PM.

It sucks to get old

Ronnies stuff was not used...

I know where the domes came from. If only sprock would post.

Whatever happened to him anyway.

Here is where my long useless list of stuff nobody cares about should go...

Proudly NOT a member of

"Team on the Teat"

Yes, I used to put huge carbs on fairly mild engines thinking the bigger the carb was the more power it would make . . That's the end of my confessions.

I am definitely no rocket scientist as the statement above proves, but here’s a few things I do know that might be fun info for those that don’t know these things . . Pre-ignition and detonation are actually two completely different animals and pre-ignition can be induced by detonation.

Pre-ignition can cause a hole in a piston which is created by high heat from the pre-ignition which can last a fairly long period of time during the up stroke . . Once the pre-ignition begiuns, it can cintinue for every stroke unless something is done to reduce cylinder temps like backing off the throttle so the holes in the pistin that are created by it are not necessarily caused by just 1 upstroke that has pre-ignition . . Pre-ignition can also shatter pistons and bend rods, detonation will not shatter a piston but it can break ring lands . . Because pre-ignition is the ignition of the fuel charge before the plug sparks, and the plug is always set to fire before the piston gets to top dead center, it actually tries to push the piston downward before it reaches TDC . . This downward force combined with the upward force can be similar to running your piston into nearly a solid concrete wall at maybe 25 feet per second, thereby possibly creating a generally undesirable affect.

Another way to explain this is this . . The fuel does not actually explode, it burns in an orderly fashion and at a particular rate . . Different fuels including different brands of gasoline have a different burn rate and this burn rate is controlled by the things the gas companies mix with their gas.

As the piston comes up above the port, it obviously starts to build compression/pressure . . When the gas burns, it obviously expands which obviously creates pressure . . Since the piston builds cylinder pressure the farther it goes upwards, and the burning gas has added additional cylinder pressure that should not be there, the cylinder pressure can become greater than the piston is designed to withstand in which case it breaks and this pressure can also cause a rod to bend if the inertia/energy of the moving piston is too great for the pressure to overcome before the piston reaches its pressure limitations.

Since the piston is attached to a lot of weight that is rotating, like the crank and rear wheel etc, the energy or inertia from this is too great for the cylinder pressure to simply stop the piston before the pressure gets high enough to break it . . it’s a bit similar to hydraulic lacking but instead of liquid the lock is created by extreme pressure.

Here’s an xlnt article on detonation and pre-ignition.

http://www.contactmagazine.com/Issue...ineBasics.html

“Detonation: Detonation is the spontaneous combustion of the end-gas (remaining fuel/air mixture) in the chamber. It always occurs after normal combustion is initiated by the spark plug. The initial combustion at the spark plug is followed by a normal combustion burn. For some reason, likely heat and pressure, the end gas in the chamber spontaneously combusts. The key point here is that detonation occurs after you have initiated the normal combustion with the spark plug.

Pre-ignition: Pre-ignition is defined as the ignition of the mixture prior to the spark plug firing. Anytime something causes the mixture in the chamber to ignite prior to the spark plug event it is classified as pre-ignition. The two are completely different and abnormal phenomenon.”

Last edited by aramid; 01-29-2015 at 11:31 PM.

So my first ride on my Tri Z ended up like this:

I wanted it to go faster so I added octane booster and held it WOT for way too long....LOL. The piston did not shatter but it did lock up. It must have been predetonation I guess. I'm about to split my cases again to reseal it due to oil leaking out. This time I'm bolting up my 310 kit, it's only been sitting around for a year now.

As I typed out the words "pre-ignition", I foresaw a post such as aramid's last. I debated on deleting my post and educating myself after work, as the terms "pre-ignition" and "detonation" echoed and clashed in my head, and that's never happened before. You all are really making me think and teaching some fantastic stuff as well. This is obviously a wealth of information that can be applied across the board as far as internal combustion goes, but it is best off in a Yamaha thread as the Tri-Z's and big-bore IT's and YZ's have had some of the worst detonation (or pre-ignition) I've ever heard hands down.

85 Tri-Zinger 60

85 ATC250SX

86 ATC250SX

87 ATC250SX

02 XR650L conversion

84 ATC 480R

Spent the last three hours measuring things.

Given that my stock head was cut I can't do a 100% stock VS Sprock comparison, but I can confirm that the angle of the squish band is close to the Sprock head as pointed out earlier on here.

However, that's where the similarities seem to end. I'll post what I can now and drawings will follow.

Diameter of combustion chamber

Mine - 66.50mm

Sprock - 69.65mm

Width of squish band

Mine - .276"

Sprock - .450"

Angle of squish band (TBD)

Close. but I think there is a slight difference. Need to make a few more measurments

Squish clearance (this needs to be drawn)

Mine - First # is distance from cylinder wall Second # is what the squished solder wire measured in that location. All #'s are in inches

0.00 - .045

0.08 - .046

0.13 - .047

0.17 - .048

0.23 - .057

0.276 - .066

Squish band ends as dome radius begins

Sprock

0.00 - .042

0.08 - .043

0.13 - .044

0.17 - .048

0.23 - .054

0.30 - .057

0.45 - 0.63

Squish band ends and dome radius begins

Before anyone takes this as gospel keep in mind this is all being done by hand with a set of .0000 digital calipers. I've got great near vision and a fair bit of measuring experience. Enough to know that it would be near impossible to duplicate these numbers to within .001" if I repeat the process tomorrow.

I also took depth measurements every 1mm across the entire chamber of the stock head. I still have to do the Sprock head. Very tedious, took 4 measurements at each point. Tossed out the high and low #'s, add the remaining two and divided by 2. If any one knows of a better way to get a profile short of cutting the head in half please let me know!

It sucks to get old

Email- onformula1@hotmail.com Rebuilt, Revalved, custom springs, lowering, forks & shocks, Custom Suspension, all brands, 2-3-4 wheeler's- PM or Email with questions.

***Check out my album for cool pictures*** http://www.3wheelerworld.com/album.php?albumid=2527

As always- Everything I post is IMHO.

Put both heads upside down and level, plug the spark plug hole up, spray the head with silicone spray, fill one head at a time with white silicone above the head deck, let them both dry for a couple of days (Thick silicone take a while to dry) pull out the molds and trim with a razor blade.

Now you can compare and take measurements and make them as you measure.

Also "CC" both heads why you are at it.

Email- onformula1@hotmail.com Rebuilt, Revalved, custom springs, lowering, forks & shocks, Custom Suspension, all brands, 2-3-4 wheeler's- PM or Email with questions.

***Check out my album for cool pictures*** http://www.3wheelerworld.com/album.php?albumid=2527

As always- Everything I post is IMHO.

I sold my Sprock kit for the Z so I cannot compare, but on the Tecate, he cut the piston crown to match the head, so the piston that came with the big bore kit was unique.

nstyle73

"When in doubt, wind it out"

Feedback: http://www.3wheelerworld.com/showthr...k-for-nstyle73

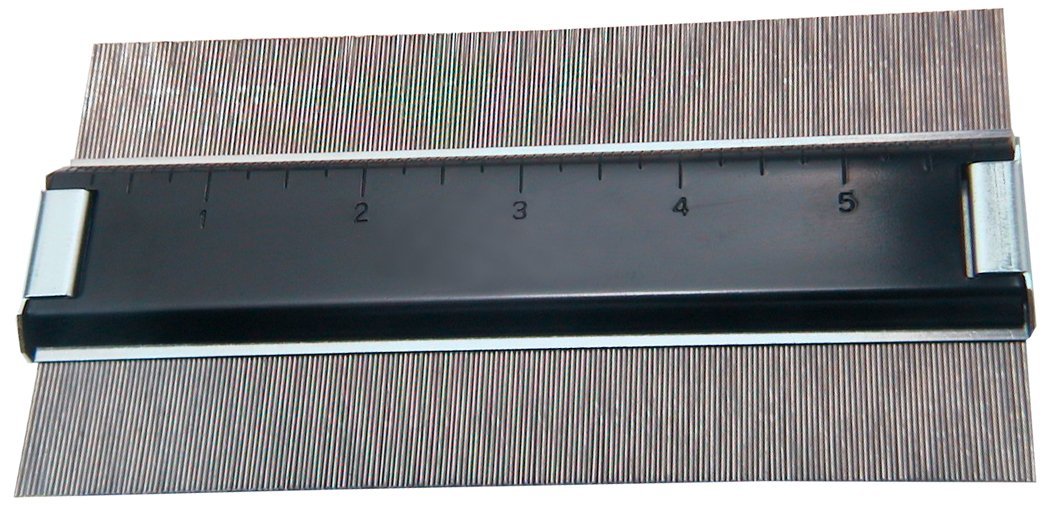

A contour gauge might work . . Just press it into the head then lay a piece of lined tracing paper on the edge of the table then lay just the pins of the gauge on the table over the paper . . Then use a pencil with replaceable lead and make a point on the lead by rubbing it on some paper . . Then, pull the lead out far enough so the body of the pencil will not touch the pins and carefully trace it without pushing against the pins too hard because they might move . . Photocopy it or go over it with something darker . . You can then lay one tracing paper over the other and compare the differences . . Of course you can measure the heights of the lines too.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Only 8 bucks at Amazon.

http://www.amazon.com/Empire-Level-2.../dp/B0000TFIBW

Sorry about the big photo.

Both great ideas guys THANK YOU!!!! CCing is still pending.

Last edited by El Camexican; 01-30-2015 at 01:28 AM.

It sucks to get old

Email- onformula1@hotmail.com Rebuilt, Revalved, custom springs, lowering, forks & shocks, Custom Suspension, all brands, 2-3-4 wheeler's- PM or Email with questions.

***Check out my album for cool pictures*** http://www.3wheelerworld.com/album.php?albumid=2527

As always- Everything I post is IMHO.

Your Sprock head photos are a little blurred, but it seems the width of your band is less than mine. The outer edge of the chamber to where the radius begins on mine is .450" (measuring the slope which is probably not the right way) Yours looks smaller in the photos. Same as the Tri-Z head. Could be my imagination, or maybe I have one of the newer domes

Last edited by El Camexican; 01-30-2015 at 09:25 AM.

It sucks to get old