Hi

Been lurking here for ages and using all the cool info to help me build a stroker motor

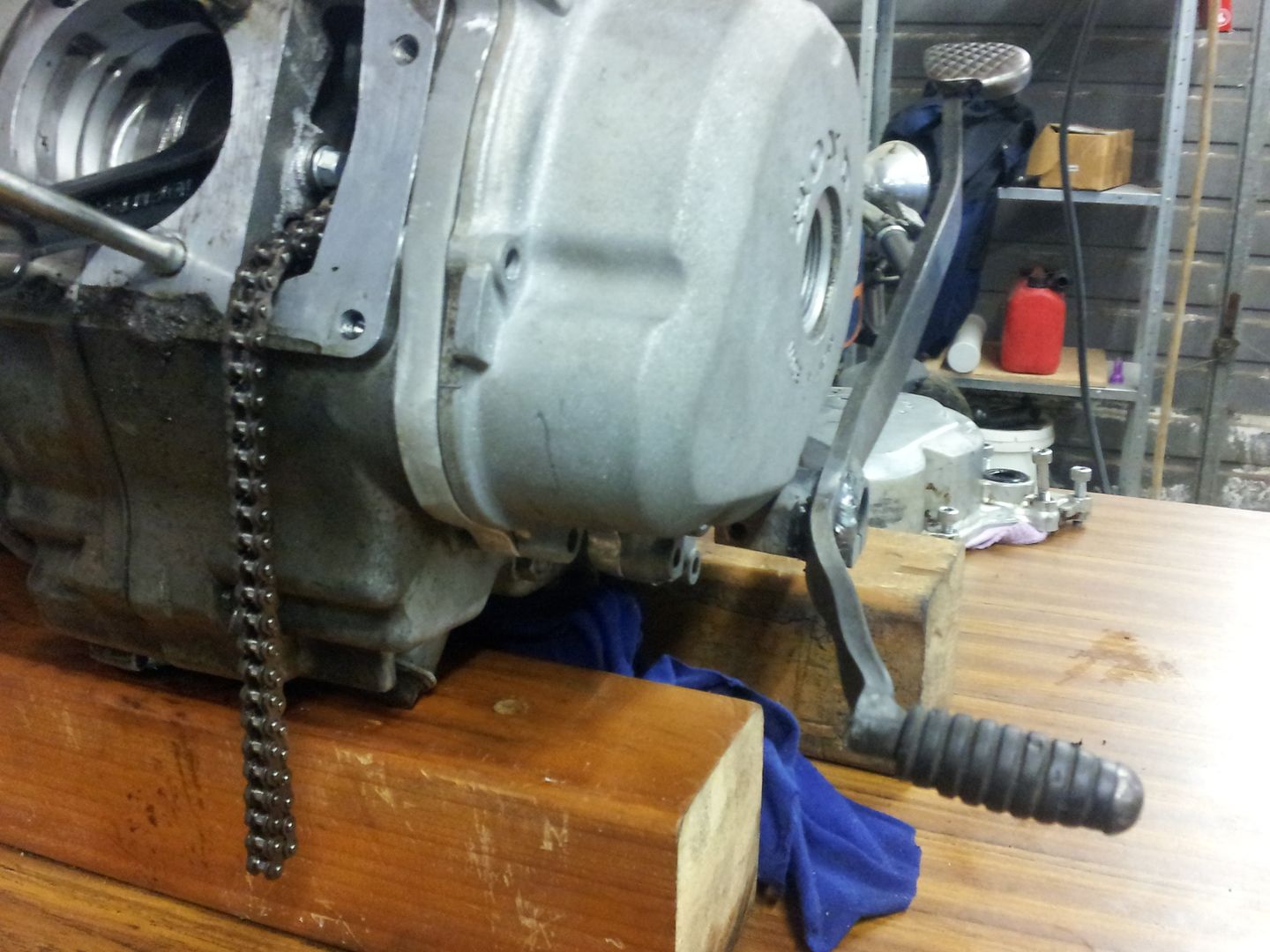

Thought i would throw up a few pics of a motor build now i have finished it.

The plan was to build a 170cc, but one of the barrels had a issue so i went back to a more reliable 150cc for now.

It started with scoring a nos helm and son atc110 58mm stroker crank.

Then i started playing around with different piston combos in the 55mm size for a 138cc using 110 and 125 barrels

But i want bigger power so two 61mm barrels were knocked up to take a couple of different pistons

This one below is going on a stock 49.5mm stroke

A 90 roller cam was used to work out how to turn a 125 cam into a roller

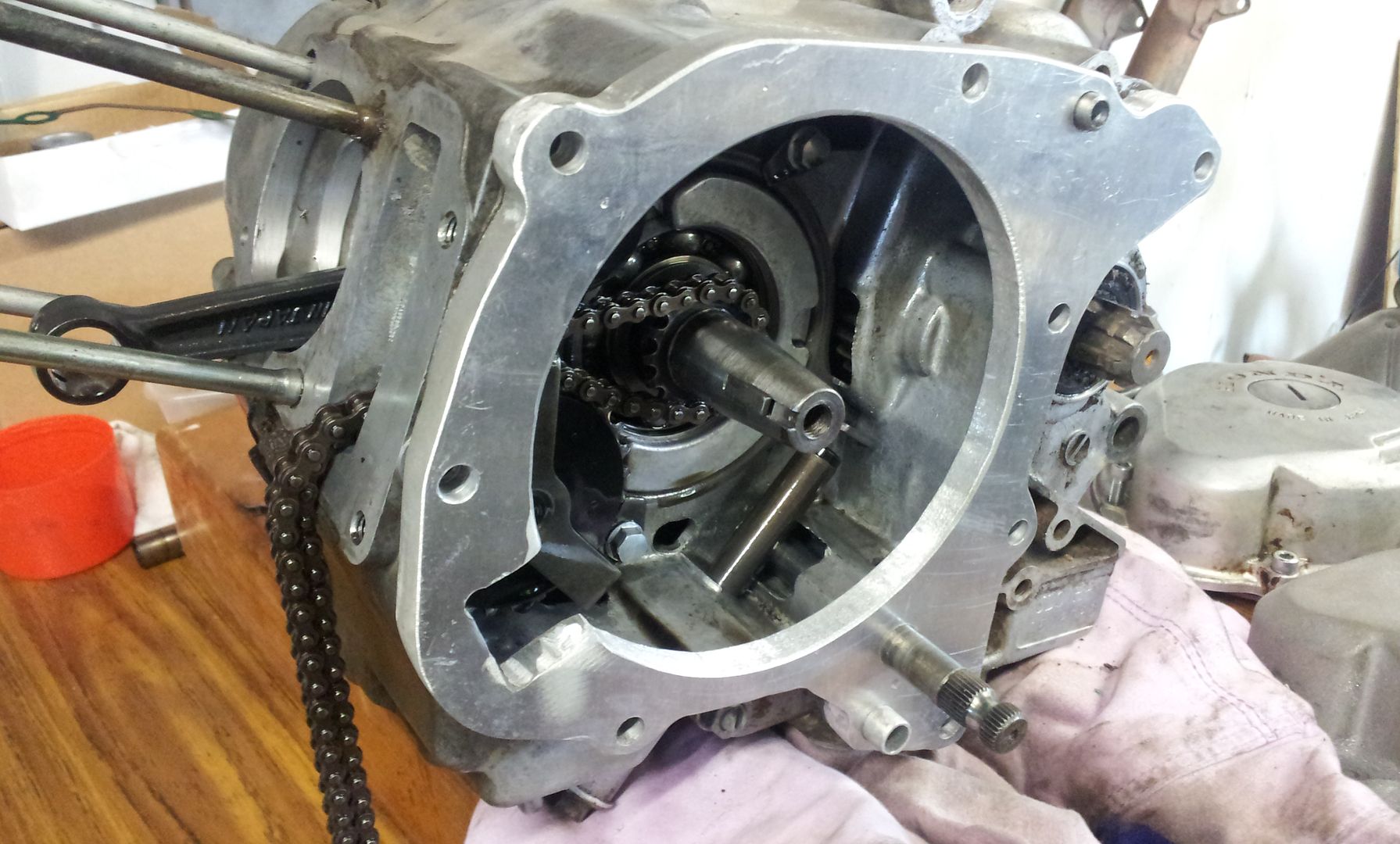

Cases bored

I have to confess this motor isn't going into a trike,if i had more time iwould love to build a little 70 with a bombed motor.

To be cont.....

Reply With Quote

Reply With Quote

.You can't just fire it up am bang it in,there is a technique .I have done about 5 sets of cases this way from 110 to take 125 barrel right up to the 61mm big bores.I have built a few tools for working on these motors but a case borer is on the too do list.

.You can't just fire it up am bang it in,there is a technique .I have done about 5 sets of cases this way from 110 to take 125 barrel right up to the 61mm big bores.I have built a few tools for working on these motors but a case borer is on the too do list.

There's nothing like the sound of screaming 2strokes and the smell of race gas in the air

There's nothing like the sound of screaming 2strokes and the smell of race gas in the air