Never get in a hurry to buy the first boring equipment that pops up. If you’re a patient person you’ll find a cycle shop in financial trouble; I’ve purchased cylinder machines for ½ of what their really worth. You need to be able to wave $100 dollar bills under their noses, cash is KING. Many times your shop is bare of equipment; the next week you might wonder where to put all of the wonderful stuff.

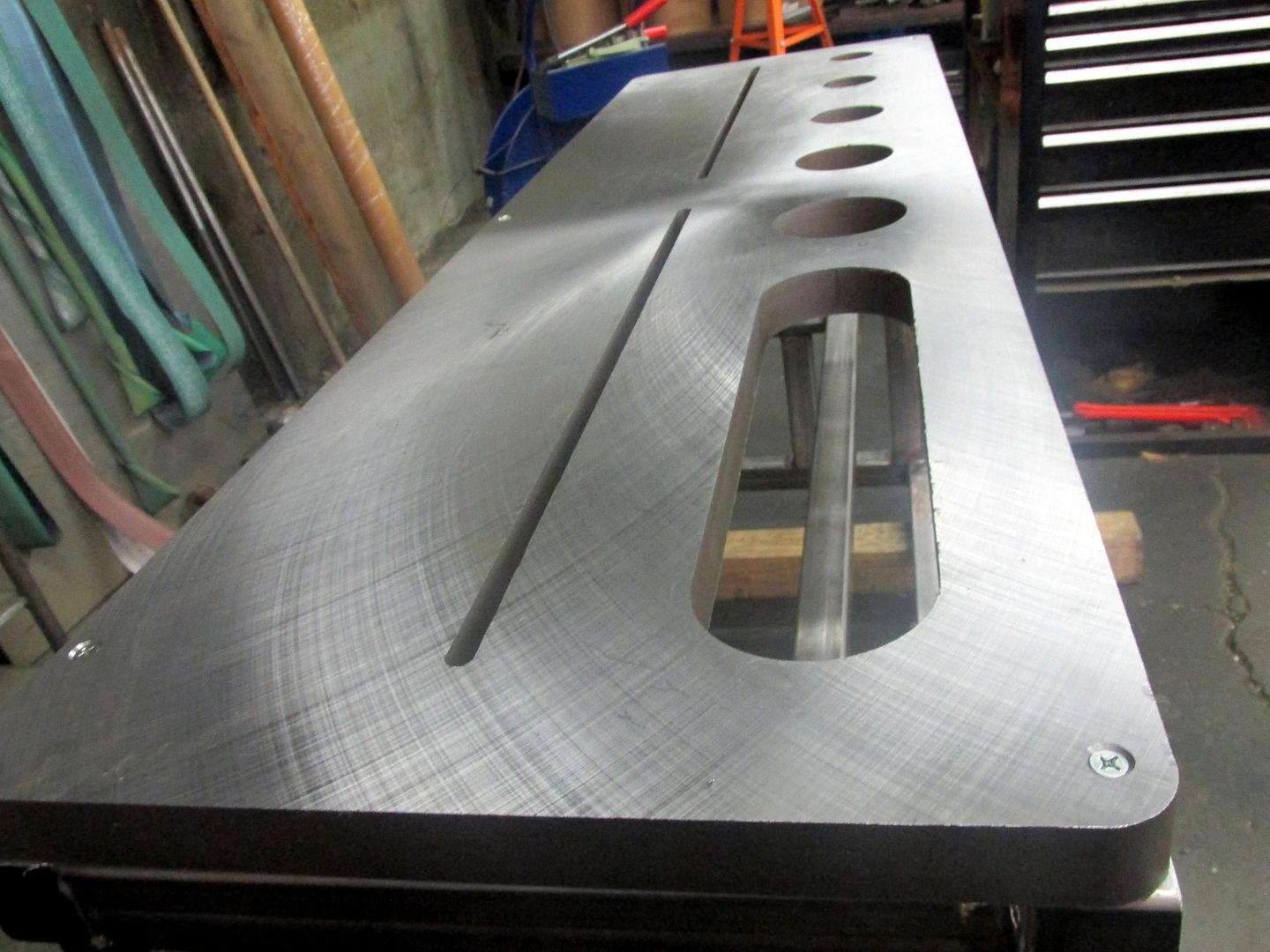

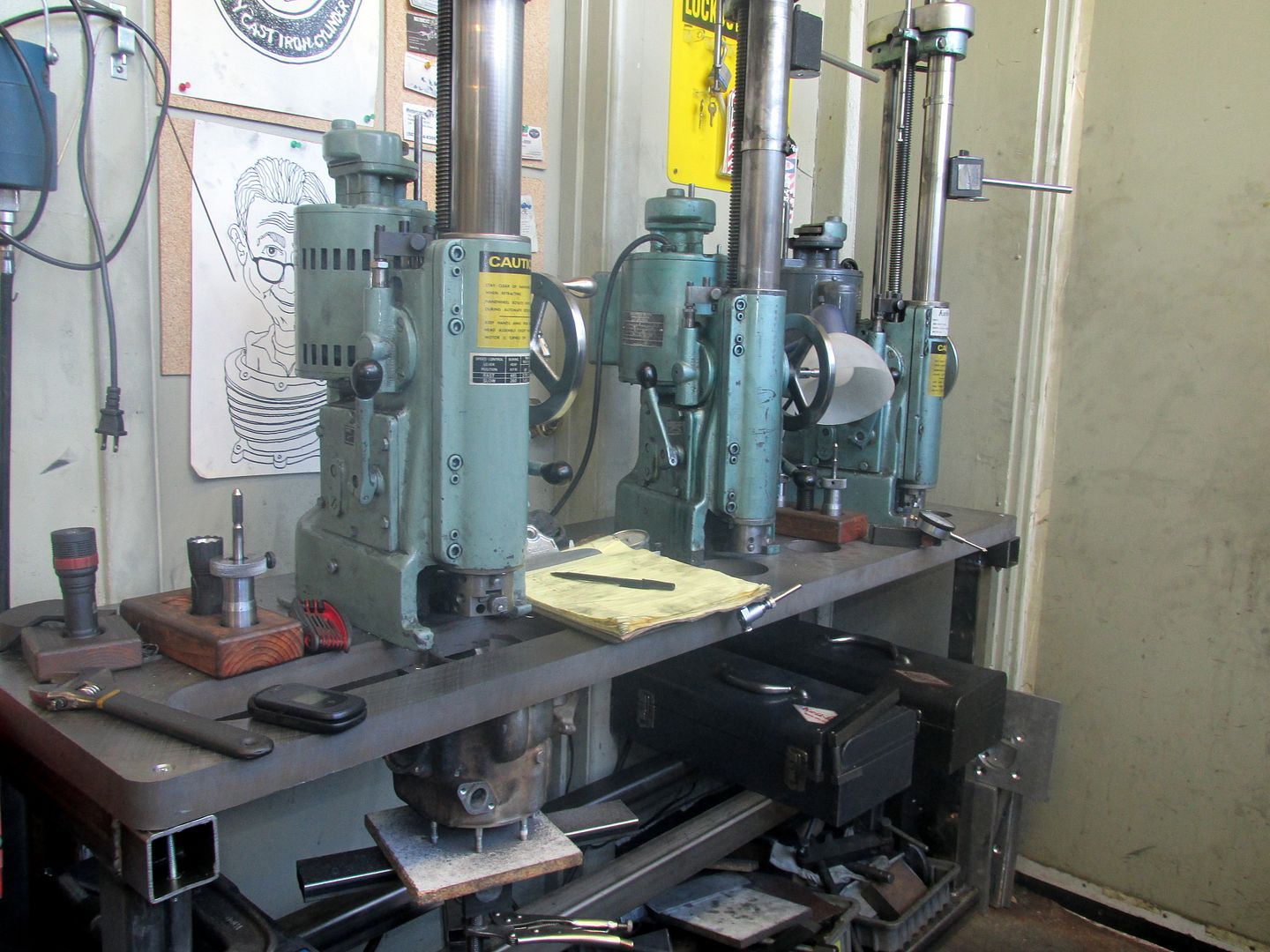

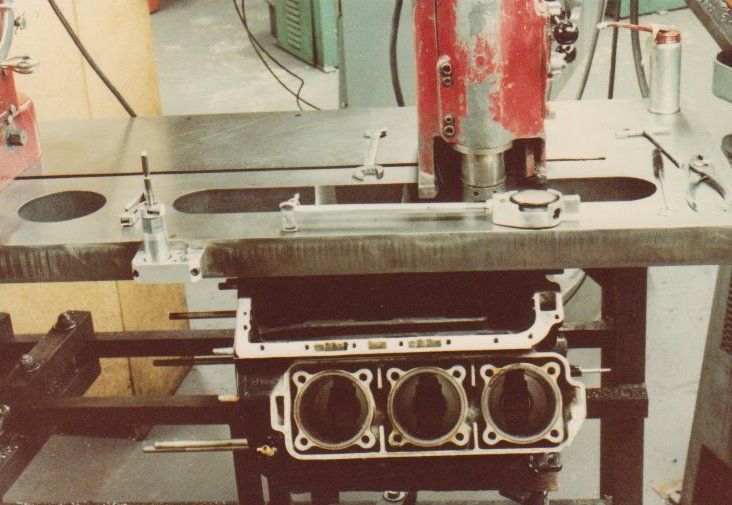

My new boring machine bench came back from the surface grinder yesterday. It’s 20” by 60”; there’s enough width so 2 machines can swap ends without worrying if 1 will fall off the table. Pictures will follow after the weekend. 1 of the older tables will go to shop #2 & I’m going to put the other for sale with an extra FWS machine. This will be a good opportunity for a fair price. My problem is my 2 extra machines are missing the tool kit especially the sets of centering fingers. CRAP

Special tables aren’t difficult to build for yourself. If you have a standard triangular boring stand; you will probably wish it was a little larger after you bore a couple dozen cylinders. It seems like they always get larger as the space becomes available.

One key is finding a shop which has a surface grinder to finish the tops & bottoms.

The small double table; A friend burned the top for free, surface grind top & bottom = $100.00. 1-1/2" square tubing $150.00 for base. A friend put together the fab work & the custom table is complete. If you're clever things can be put together for less than an ARM & a LEG. With this Old Dog's bad back; I can only do the sit down projects.

Stay Tuned

JT

Reply With Quote

Reply With Quote