Tri-z base gasket blown out?

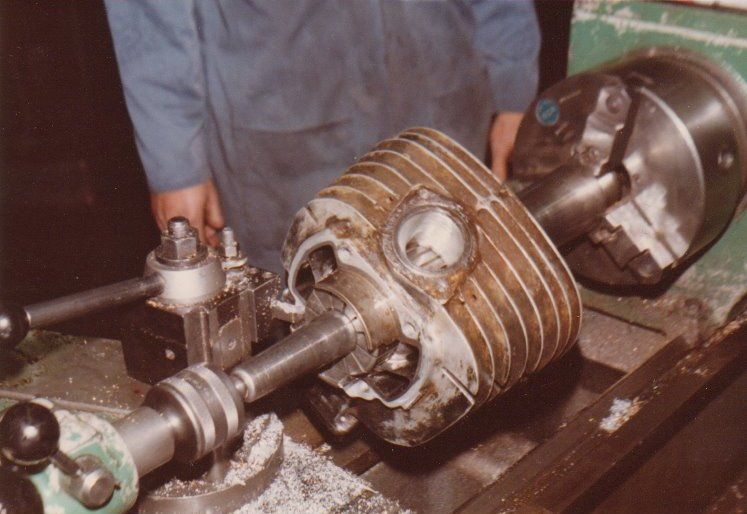

I got a 85 Tri-z with a fully rebuilt motor with some minor mods from the yamaha wrench report like raising the exhaust port a little and shaving the head with stock carb and dg pipe. Didn't even have 3 hours on the engine until it died on me and noticed it lost almost all compression. Then I noticed the base gasket just below the pipe was blown out. I followed everything to torque specs when putting it back together. How or why would this happen?

Sent from my iPhone using Tapatalk

83 Honda 250r

85 Honda 70

83 Honda 185s

85 Yamaha Tri-Z (restoring)

83 Honda 70

79 Honda 70

74 Honda Z50

78 Harley Davidson Golf Cart w/Big Red Engine!!!

Reply With Quote

Reply With Quote AKA Ronnie use to tell me to use a center punch and slightly dimple the bottom end where the cylinder rests. The 250R has a thin area I always did.

AKA Ronnie use to tell me to use a center punch and slightly dimple the bottom end where the cylinder rests. The 250R has a thin area I always did.