The Clymers manual isn't always the best, compare it with the Honda manuals too. Honda made the machine, so in theory their in house made

service manual should be the most accurate.

http://www.oscarmayer.net/atc/manuals/

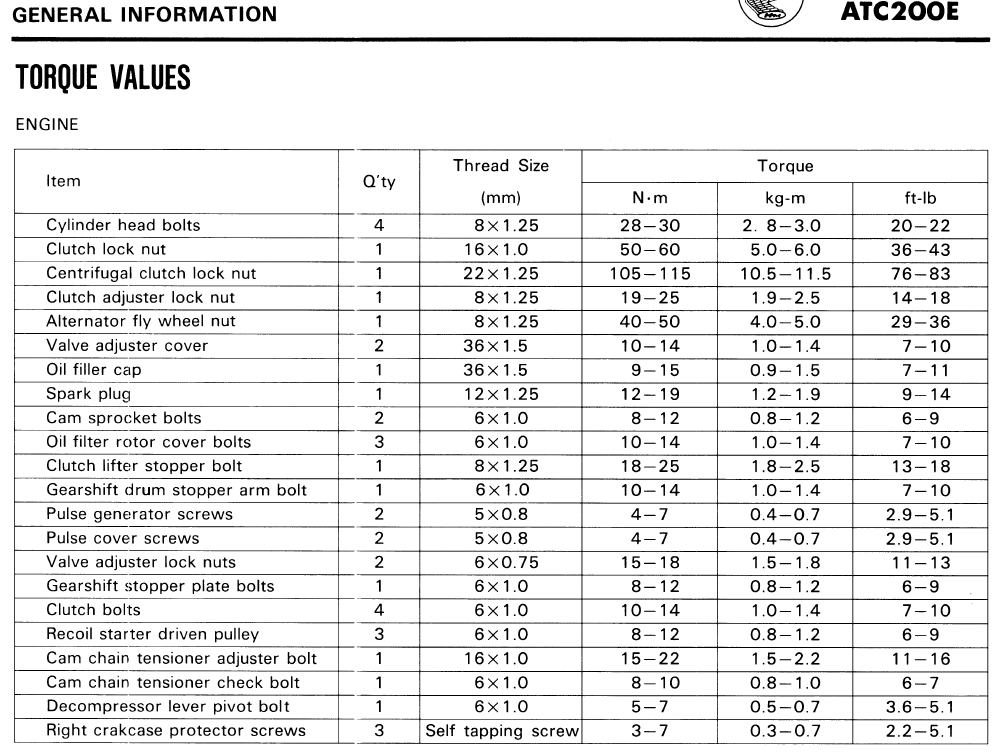

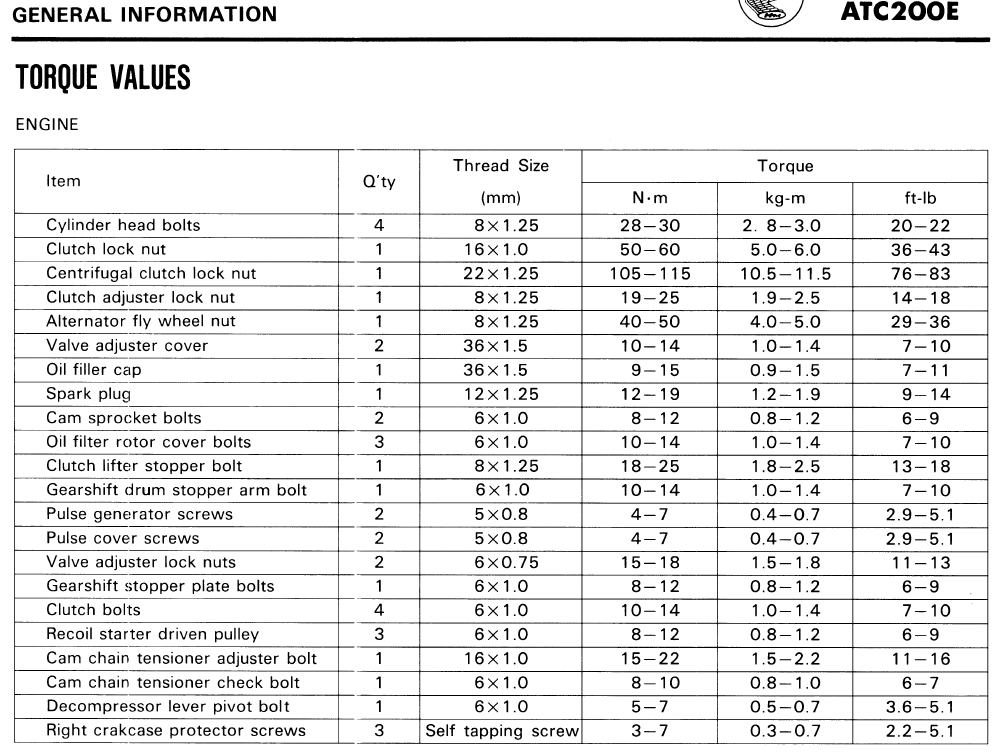

Anyway, finding the torque specs can be a bit of a chore to find. I found the flywheel nut spec under general info. It says 29-36 ft-lbs. Did you replace the key that was sheered? With the key + the given torque spec and blue loctite it shouldn't back out. If it does, then the taper on the crank/flywheel might be damaged too much from running loose. Also make sure the threads are in good shape and such, maybe your not actually getting tight on the flywheel, but instead hitting a bad spot.

Reply With Quote

Reply With Quote ." That's it, no torque spec. This bolt keeps backing out after riding and pulling pullstart. My impact driver isn't strong enough, and I don't know what they mean by using a

." That's it, no torque spec. This bolt keeps backing out after riding and pulling pullstart. My impact driver isn't strong enough, and I don't know what they mean by using a