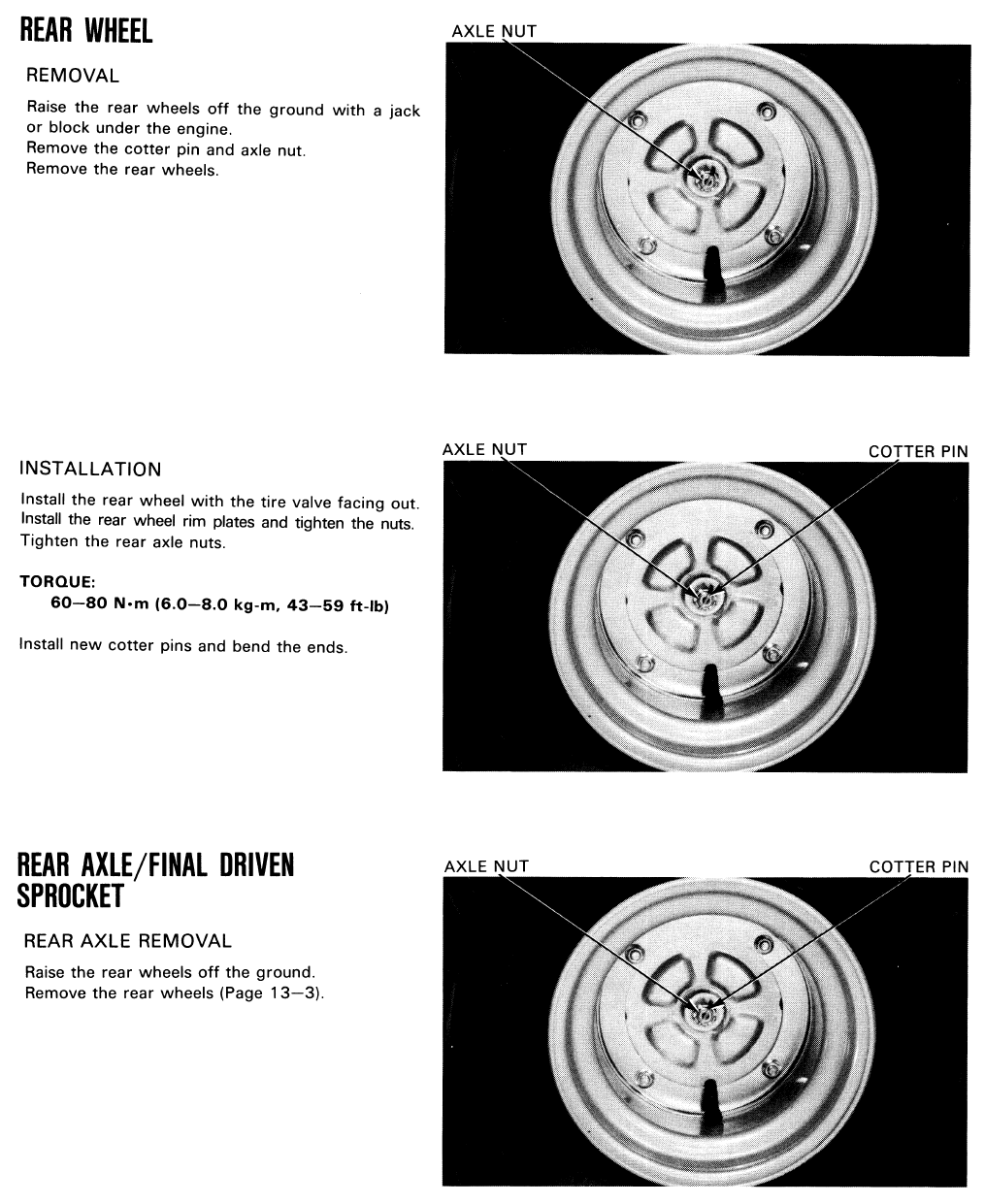

Alright, back home and on a real computer. The axle nut torque spec is 43-58 ft-lb.

As for the cotter pin, basically it's for the just encase. If the nut comes loose, it will work it's way off fairly quickly with out something stopping it from coming out. If the nut comes off all the way, the whole wheel can fall off and case a bad day. That style of nut is called a castle nut, and it's common on steering

parts for cars and trucks too, it's safety for them so if the nut comes loose, you'll still be able to steer the vehicle.

Another thing to note is the splines on the hub can get worn if the nut is loose. When you move the tire, there should be no slop or free play between the tire moving and the axle moving. If there is, the splines likely won't last long due to the movement. It's not a bad idea to grease or lube up the splines to prevent rust and make taking it apart next time a bit easier.

Also, FYI, the square bolt pattern you mention isn't standardized at all. If I recall correctly it's a 4x130 bolt pattern (4 bolts, 130mm circle for the spacing). 4/110 is much more common for Honda and I know they go upto 4/150, maybe even bigger than that. Same goes for 5 lug and 6 lug for cars & trucks.

Anyway, if you're not aware, you can unbolt the 4 lug nuts that holds the rim to the hub to remove the tire. No need to touch the axle nut which holds the hub onto the axle. Walmart and pretty much any other place that sells & mounts tires can swap the tires over for you, shouldn't be expensive, maybe even free if you buy the tires from them. You could also bring the whole machine to them, but personally I'd just bring the tires to have them swapped over on the stock rims.

For the cotter pin, I would think the automotive section should have some replacements. They make different sizes, so you'll want to find one small enough to fit, but big enough to stop the nut, doesn't have to be perfect, just close.

I have no experience with that brand of tire, but when I google it, it comes up as a 22x11-8, but stock is 25x12-9. The first number is height, second is width, and 3rd is rim size all in inches. You'll likely want to match the height and rim size, width isn't quite as critical as long as it doesn't rub anything.

Some tires are heavier than others, but it sounds like you're not an extreme rider, so you probably won't notice the difference much. Long story short, the OEM 3 wheeler tires are soft and made for a real light machine, most atv tires today are made for quads and side by sides so they tend to be thicker, heavier, and stiffer riding.

Just did a quick ebay search for the cheapest new tires and the same brand comes up that you mentioned, maybe it's the same thing? it says it's 4 ply, max load 430lb per tire (860lb for the rear). Sounds like it's closer to a quad tire but probably would work fine, just maybe a tad on the stiff side.

https://www.ebay.com/itm/25x12-00-9-...MAAOSwlAZaVS5k

Here's more of a 3 wheeler tire that's the right size, 2 ply and lighter tire which would give a better ride. If you work your machine the stiffer tire could be a benefit for you. I've had good luck with the Kenda brand.

https://www.ebay.com/itm/25x12-9-Ken...UAAOSwAy5aouQ2

I haven't really had a real problem with cheap tires, but I don't live in the desert or have plants with big thorns etc.

Reply With Quote

Reply With Quote

tool he used). The screwdriver looking thing is a tire core remover, got one that looks exactly the same as his, same with the tire spoons. For car tires it's stupid easy, or in his case a light truck tire. I've done old like 50's era split rim semi truck tires this way that sat for 30+ years from my grandpa's house when he sold his property. He had a stupid amount of old tires for some reason, took around a week to load up a 8x12 flat bed trailer with the rim free tires to take to the tire recycler and then afterwards hauled in the rims as non-ferrous steel to the scrap yard. The money from the rims paid to get rid of the tires. Not sure what it is about Michigan, but the property I bought had a pile of tires too, sadly very few with rims though, probably around 40 car/truck tires though.

tool he used). The screwdriver looking thing is a tire core remover, got one that looks exactly the same as his, same with the tire spoons. For car tires it's stupid easy, or in his case a light truck tire. I've done old like 50's era split rim semi truck tires this way that sat for 30+ years from my grandpa's house when he sold his property. He had a stupid amount of old tires for some reason, took around a week to load up a 8x12 flat bed trailer with the rim free tires to take to the tire recycler and then afterwards hauled in the rims as non-ferrous steel to the scrap yard. The money from the rims paid to get rid of the tires. Not sure what it is about Michigan, but the property I bought had a pile of tires too, sadly very few with rims though, probably around 40 car/truck tires though.