Hi all, been awhile since I been on, hope all is well.

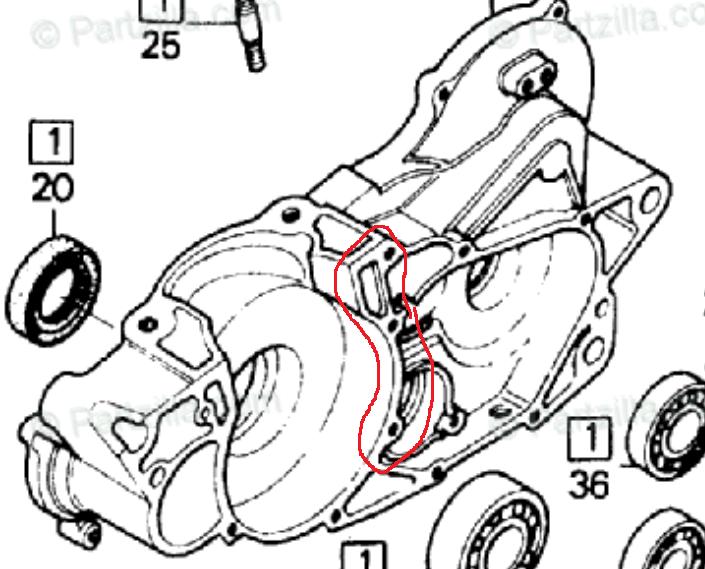

I picked up a 86 250R ATC and gave it a fresh bore .030 with a new piston due to cylinder scoring. Rings are in spec, newer carb is cleaned and float height is correct. New reeds. Compression is tight. The bike keeps flooding the crankcase with gas and now when I drained the oil in the transmission case, it is full of gas. I thought possibly the carb, and switched it out with another carb...and same thing. It will start after some time, but it's extremely hard to get it started and running pretty rich from the load of gas in it.

Any ideas on this issue? Any help would be appreciated!

Reply With Quote

Reply With Quote