The cleanness of

parts don't mean much, inside an engine with bad bearings but a fresh oil change will look brand new yet xD.

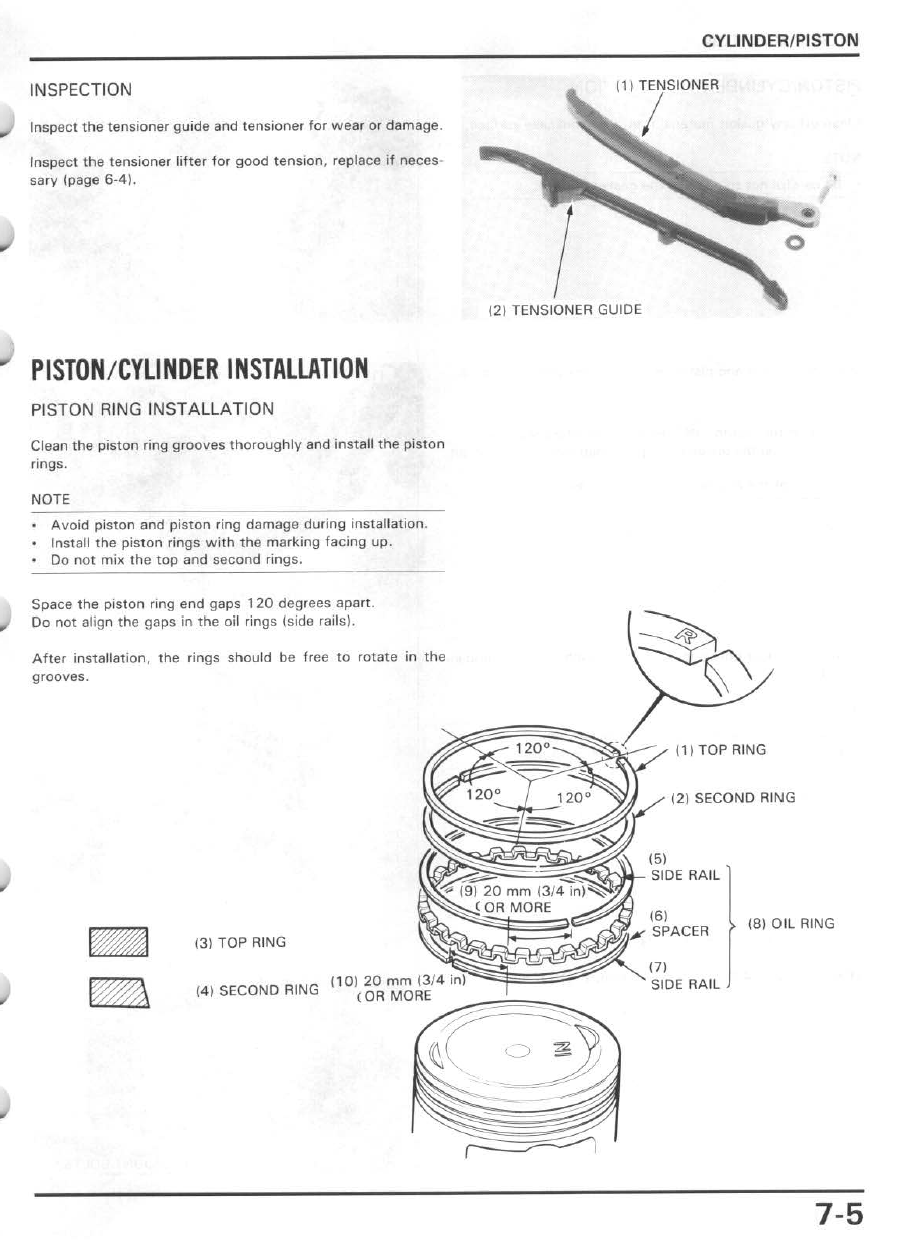

You can check the ring wear by putting just the ring in the cylinder, square it up with the piston, and measure the end gap. Top two rings should be 0.5mm (0.020 in) or less. Standard is 0.15-0.3mm (0.006-0.012in). Oil ring spec is 0.2-0.7mm (0.008-0.028in).

Just for the sake of making sure we identified the problem correctly, check your ring gap, careful removing the rings, they are brittle and very easy to break.

The second side of the timing chain tensioner is bolted in on the bottom side under the right side cover.

Also, it looks like the oem/standard piston, I'd check the face of it carefully for any numbers or like STD. If you have a caliper measure and see what the bore size is. Generally it's based in mm. Standard bore is 74mm (2.91in). This will tell you what rings you'll need to order. There's also special tools to measure the cylinder to check if it's out of round, if the bore tapers, etc. It wouldn't hurt to see if you can either get the tools for that, or see if you could pay a machine shop to measure it for you. If it's worn too much, you'll have to have the cylinder bored which is a machine shop process, not a DIY thing. Also before you assemble you'll want to buy a hone or pay a machine shop to hone it. A hone effectively is to resurface the cylinder walls so the new rings can break in, the tool is quite cheap.

Not sure how "correct" of a build you'll want to do. I'd suggest checking the crank and rod out, measure the cylinder to make sure it's good, check out the head for any cracks (don't think these are common for head issues), lap the valves, replace valve end seals, check the guides, rocker arms, etc. Basically all the

parts you can access with out a major tear down of the engine.

Service manual should have all the specs and how to check the

parts.

Just honing the cylinder, slapping new rings in (the correct size), lapping the valves and putting it back together can get you back up and running, but checking the

parts out will make sure there's no future problems.

Reply With Quote

Reply With Quote