Before I get this right. It's frust. Broke this one in strict, 3 heat cycles up to 200F and back down, warm up, first ride 1/3 throttle, 2nd 2/3, 3rd did a plug chop and it came up black.

Refreshing your memory; bike didn't run when I bought it. eBay top end, k&n filter on back of stock carb, no silencer, stock header.

Orig 152 main, wouldn't rev unless needle was all the way down. Verdict was bore is too tight, or didn't break in properly/warm up.

Put top end on last night, broke in. 145 main jet. Plug chop is black/ very dark tan.

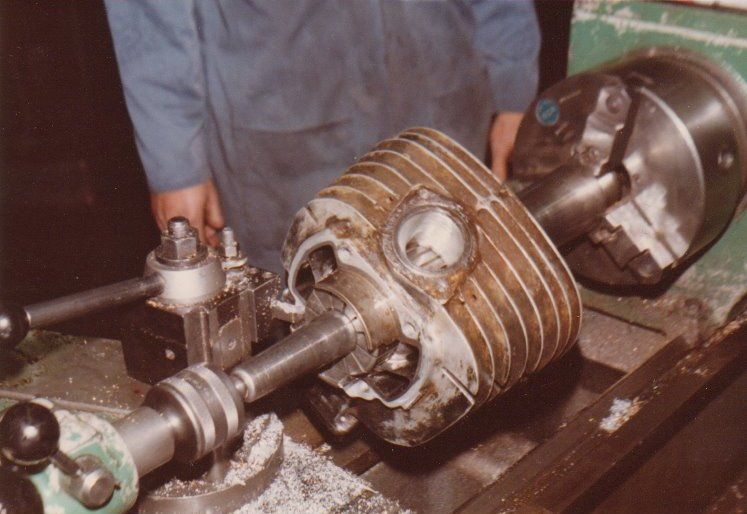

Pulled the piston off, carbon on top of piston, head is black and oily. I was just going home from a short 15 min ride, the beginning of which I let it idle for 15~min, until cylinder was ~155 and not rising anymore.

Now, 2/3 times I've seized the top end its been at 1/3 throttle. At the end of my first break in ride today, I rode over to my house never going over 1/3 throttle. 3/4 mile ish. At the end of my ride cylinder temp was 280F! Which shouldn't be alarming EXCEPT it was under very minimal load the whole time, not riding it hard with no airflow.

I think it's an issue with my needle. Idling during break in the plug was still white. Running rich enough to deposit carbon on top of the piston really only makes sense if the main is too rich, since the needle doesn't come into play after ~3/4 throttle.

I put the top end back together as is. Not too keen on ruining another piston while figuring out jetting. Swapped the main out with a 140

Reply With Quote

Reply With Quote

Ride free,Brotha. See you in Heaven.

Ride free,Brotha. See you in Heaven.