I sure appreciate the feedback ! Thanks.

I too, don't want to get things too large. It may be hard to tell from the pics so I'll explain how and what was done:

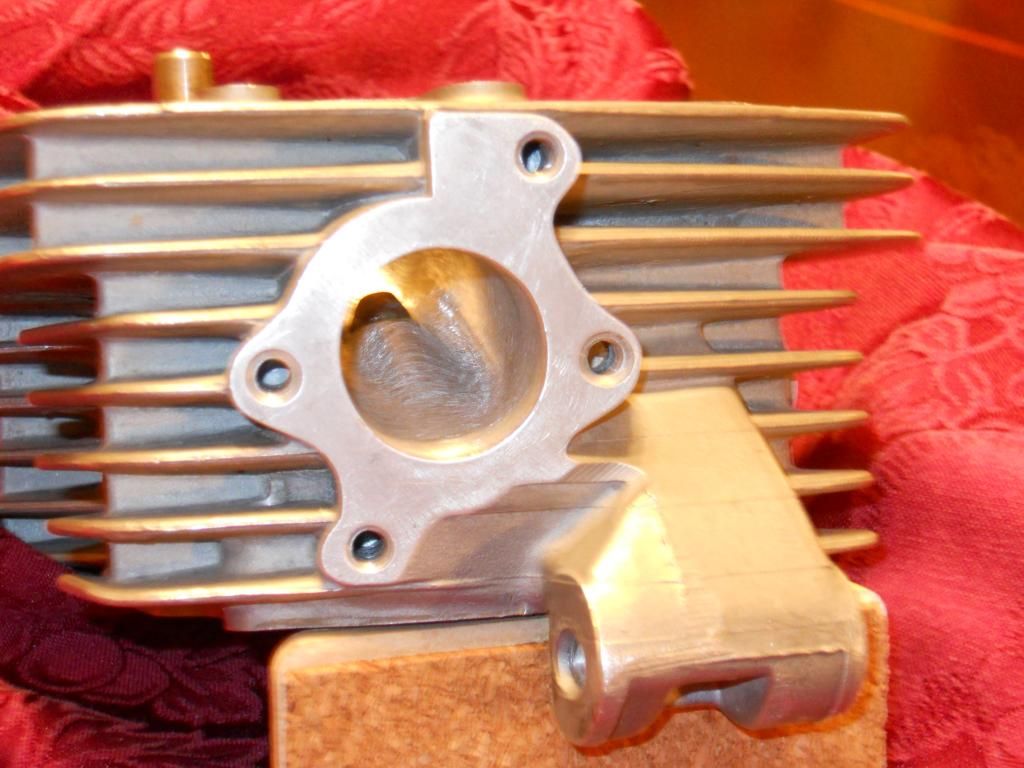

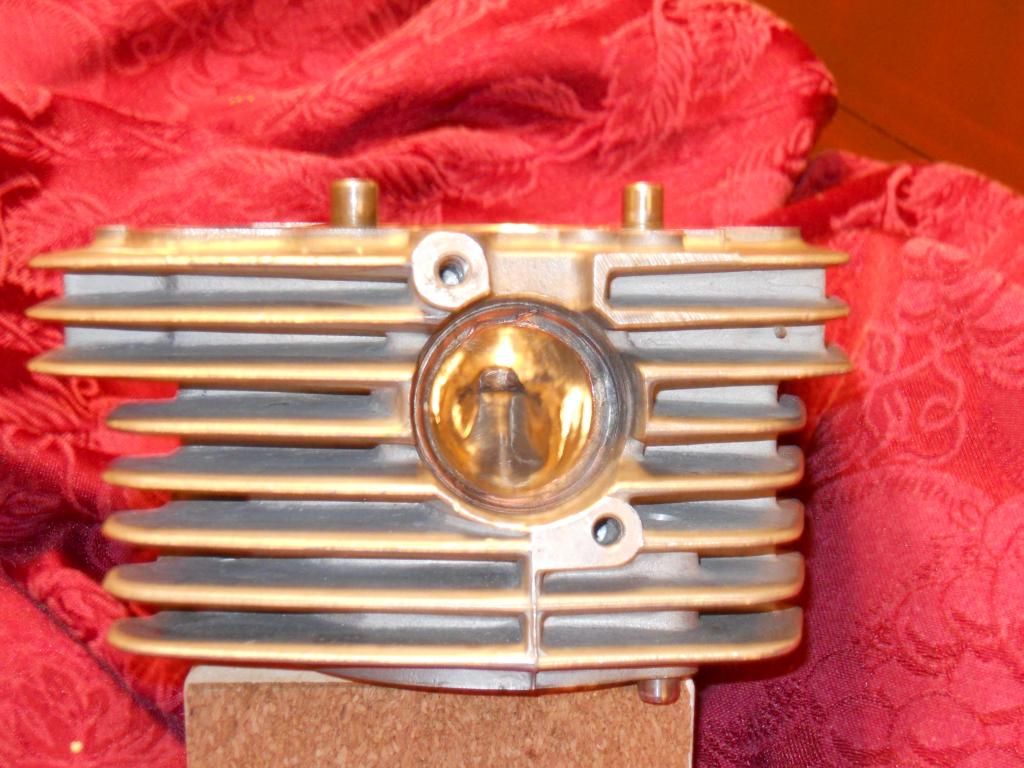

I've blended/port matched the intake side to 30mm (same as the intake and carb) and sloped the pocket to create a smoother transition below the seat. Stock, the pockets nearly make a 90 degree bend and have very little taper from the bottom of the valve seat all the way out the port. This I've certainly changed. Also, with this change, the reduction in diameter from 30mm down to ~ 26mm at the intake valve seat, I suspect that the charge velocity will increase going through the seat/valve.

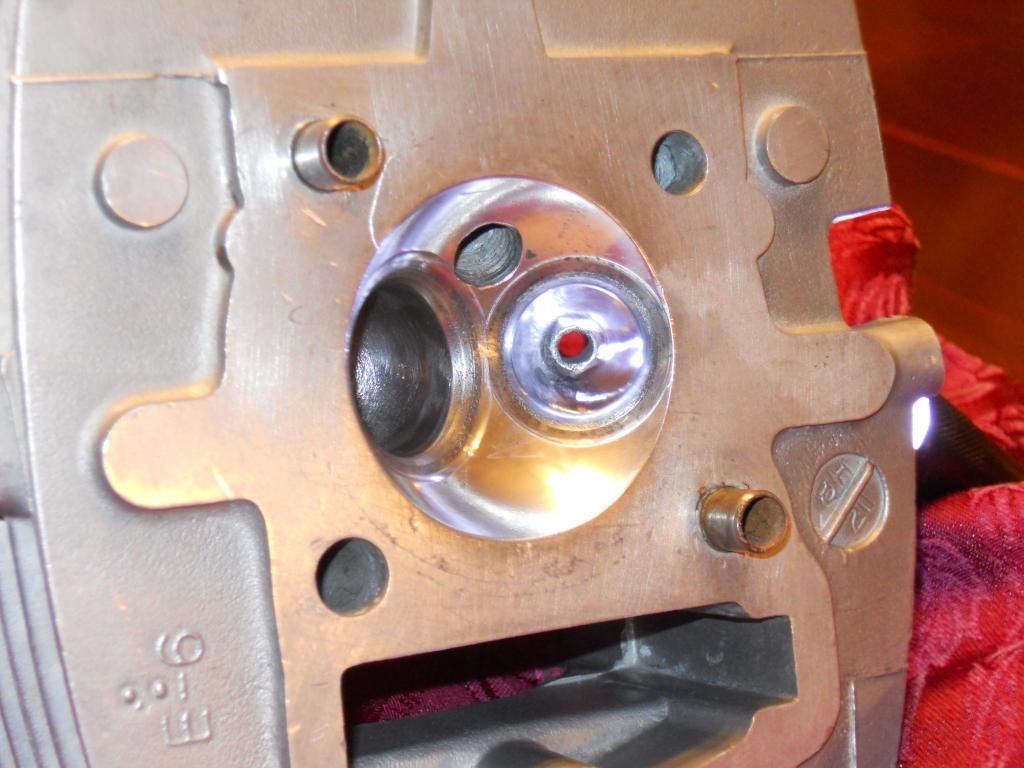

On the exhaust side, things are very similar with gradual sloping of the pocket near the valve guide and an increasing taper out to the copper o-ring. In both cases, I reduced the size of the valve guide bridge a bit, hoping to gain a bit more capacity on the higher RPM spectrum.

Time will tell. If it runs like crap, is doggy on the bottom end and won't pull itself around in first gear, I still have a couple more heads that could be bolted on.

The Goal... All I Need Is The Time...

Reply With Quote

Reply With Quote